Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Send e-mailvip@zhongzaisheng.com

The DS2140 small shredder has the characteristics of compact structure, easy operation, and high shredding efficiency, and is suitable for shredding various materials such as wood, branches, waste paper, and plastic. The device is driven by a motor to rotate the blade roller, utilizing the shearing and pulling effects between the blades to shred the material into small pieces or granules, facilitating subsequent processing and recycling.

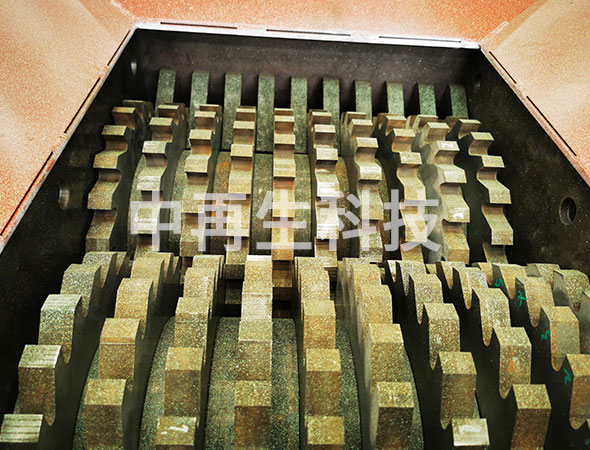

The working principle of the DS2140 small shredder is mainly based on the interaction between the blades. After the equipment is started, the motor drives the knife roller to rotate through the reducer. The knife roller is equipped with multiple blades, which are distributed in a specific spiral arrangement. When the material enters the shredder, it is grabbed by the blade and continuously sheared and pulled by the rotation of the blade roller. After multiple cuts and pulls, the material is eventually torn into small pieces or granules and discharged from the discharge port of the equipment.

The main body of the main equipment of the shredder is welded with high-quality steel plates for stress removal treatment and machined as a whole to ensure the stability of the equipment under heavy load for a long time.

The bearing / seal bearing seat adopts the patented split type, which can quickly remove the moving tool, fixed tool, bearing and other components, and is easy to maintain and replace the tool. The unique sealing structure effectively blocks the contact between broken objects and grease, and the treatment of liquid materials can also protect bearings and gears.

The moving tool / fixed tool moving tool material is made of special alloy tool steel forging blank, precision machining, multiple heat treatment and low-temperature freezing heat treatment technology. The overall toughness and hardness are consistent and can be reused to ensure the cutting performance and service time. The fixed tool is installed with a patented hook, which optimizes the tool replacement function and makes the tool maintenance and replacement better.

The cutter shaft is made of high-strength heavy-duty special steel, which provides powerful power for cutting with more reasonable cooperation with the cutter.

| Model | Power(kW) | Grinding chamber dimension(mm) | Total Weight(t) | Size(mm) |

| DS2140 | 7.5 | 400X430 | 1 | 1310X1080X1840 |

| DS2160 | 15+15/4 | 600X550 | 3 | 2620X1120X1810 |

| DS2180 | 15+15/4 | 600X550 | 3 | 2620X1120X1810 |

Solution