Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Send e-mailvip@zhongzaisheng.com

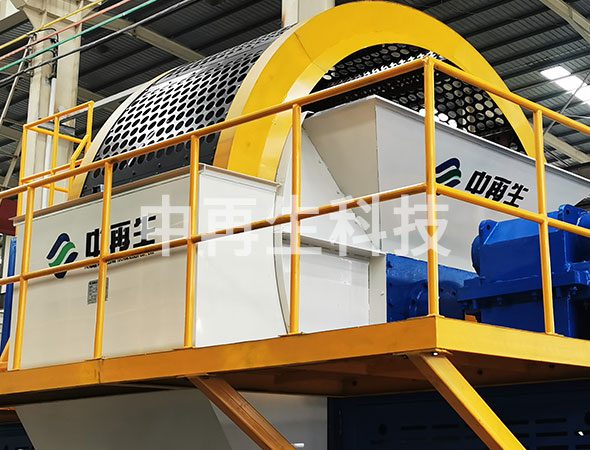

The DS44140 Series Used Tire Double Shaft Shredder is a powerful machine designed for breaking down used tires into smaller pieces or shreds. It is primarily used in the recycling industry to reduce the size of tires for further processing or to create materials like rubber crumb, fuel, or construction aggregates. The shredder can handle various types of tires, including passenger vehicle tires, truck tires, and even larger industrial tires.

The DS44140 Scrap Tire Double Shaft Shredder are equipped with multiple interlocking blades or cutters. As the shafts rotate in opposite directions, the blades pull in the material and shear it through a combination of cutting, tearing, and crushing forces. This process reduces the material into smaller pieces.

The dual-shaft mechanism ensures effective shredding of large and heavy tires.

Built with high-strength materials to handle tough and abrasive rubber materials.

Adjustable blade spacing allows for flexibility in the size of shredded output.

| Model | Power(Kw) | Shredding chamber size(mm) | Main blade quantity(pcs) | Dimension(mm) |

| DS3580 | 22+22 | 840X800 | 28 | 3300X1300X2260 |

| DS40130 | 37+37 | 1350X95 | 32 | 3600X2260X2670 |

| DS46150 | 90+90 | 1570X1080 | 26 | 5880X2000X2730 |

| DS61180 | 55+55 | 1800X1800 | 24 | 5800X3770X4550 |

| DS64250 | 132+132 | 2450X1520 | 32 | 7200X2200X3660 |

Solution