Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Send e-mailvip@zhongzaisheng.com

DS46120 series shredder features low speed, high torque, high productivity, strong power, high stability, large shear force, good shredding effect and low noise,The blades on the two shafts cut each other to complete the requirements for tearing up materials. The size of the torn material is related to the thickness and number of teeth of the torn blade. The thinner the blade, the smaller the size of the broken material.

The DS46120 series shredder is widely used for crushing and reducing solid waste, such as wood, plastic, metal, etc. It has significant application effects in urban waste treatment, agricultural waste treatment, industrial waste treatment and other fields. At the same time, the device is also suitable for recycling various solid materials and difficult to handle materials, such as plastic containers, plastic buckets, plastic films, fibers, paper, etc.

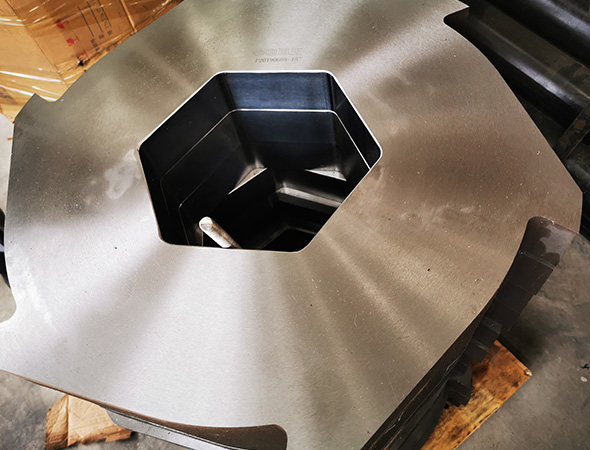

The integral cutter box is designed and processed as a whole, with high mechanical strength, high stability and reliability; The cutter box is divided into upper and lower parts, which is convenient for overhaul and maintenance and shortens the downtime. The overall annealing treatment eliminates the prestress caused by welding, which is not easy to deform after long-term use, with better comprehensive performance and longer service life.

The tool is made of imported alloy steel, with high wear resistance and moderate toughness. It is processed by high-precision machine tools, with significantly improved mechanical properties and greatly extended service life. The tool can be repaired by surfacing for many times to save the use cost and prolong the service life.

Dual three-phase asynchronous motor + dual planetary reducer drive and hydraulic motor drive are available. The motor + reducer is connected by German standard spline, with stable torque transmission, high precision and good guidance, giving the equipment strong power; Hydraulic drive, stepless speed change, strong material adaptability.

| Model | Power(kW) | Grinding chamber dimension(mm) | Total Weight(t) | Size(mm) |

| DS46100 | 55+55/6 | 1090X1080 | 8 | 5400X2000X2730 |

| DS46120 | 75+75/6 | 1210X1080 | 17.5 | 5520X2000X2730 |

| DS46150 | 90+90/6 | 1570X1080 | 18 | 5880X2000X2730 |

| DS46180 | 90+90/6 | 1810X1080 | 18 | 6120X2000X2730 |

| DS46200 | 90+90/6 | 1810X1080 | 18 | 6120X2000X2730 |

Solution