Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Send e-mailvip@zhongzaisheng.com

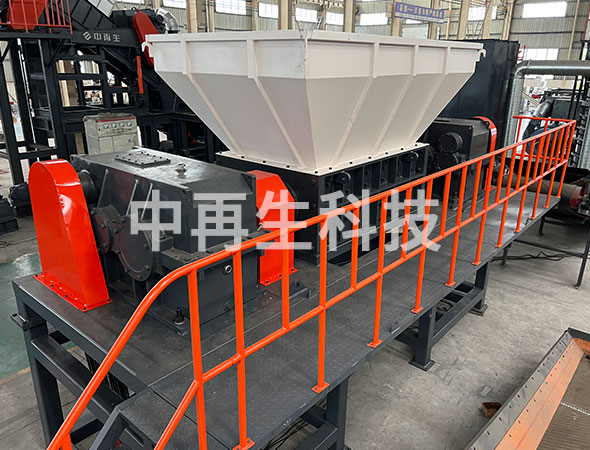

The DS46180 dual axis shredder adopts dual axis independent drive to generate corresponding pressure on the material during production, achieving automatic feeding function. This device has a unique shaft structure and a four corner rotating tool, which can avoid the phenomenon of shaft entanglement or equipment jamming during low-speed and high torque production processes, thereby improving production efficiency.

Equipped with functions such as fully hydraulic adjustment of discharge particle size and fully hydraulic top opening replacement of vulnerable parts, the operation is simple and practical. The heavy-duty rotor adopts integral welding technology, which has high precision, strong impact resistance, and reduces current fluctuations during operation. At the same time, the casing is made of high-strength steel, the plate hammer is made of high wear-resistant materials, and the rotor is made of low temperature resistant high-strength steel to ensure the durability and stability of the equipment. The device maintains low noise and low energy consumption during operation, making it environmentally friendly.

The integral cutter box is designed and processed as a whole, with high mechanical strength, high stability and reliability; The cutter box is divided into upper and lower parts, which is convenient for overhaul and maintenance and shortens the downtime. The overall annealing treatment eliminates the prestress caused by welding, which is not easy to deform after long-term use, with better comprehensive performance and longer service life.

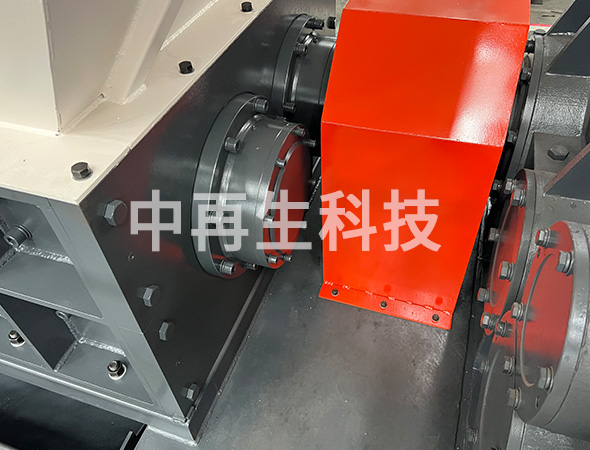

The tool is made of imported alloy steel, with high wear resistance and moderate toughness. It is processed by high-precision machine tools, with significantly improved mechanical properties and greatly extended service life. The tool can be repaired by surfacing for many times to save the use cost and prolong the service life.

Dual three-phase asynchronous motor + dual planetary reducer drive and hydraulic motor drive are available. The motor + reducer is connected by German standard spline, with stable torque transmission, high precision and good guidance, giving the equipment strong power; Hydraulic drive, stepless speed change, strong material adaptability.

| Model | Power(kW) | Grinding chamber dimension(mm) | Total Weight(t) | Size(mm) |

| DS46100 | 55+55/6 | 1090X1080 | 8 | 5400X2000X2730 |

| DS46120 | 75+75/6 | 1210X1080 | 17.5 | 5520X2000X2730 |

| DS46150 | 90+90/6 | 1570X1080 | 18 | 5880X2000X2730 |

| DS46180 | 90+90/6 | 1810X1080 | 18 | 6120X2000X2730 |

| DS46200 | 90+90/6 | 1810X1080 | 18 | 6120X2000X2730 |

Solution