Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

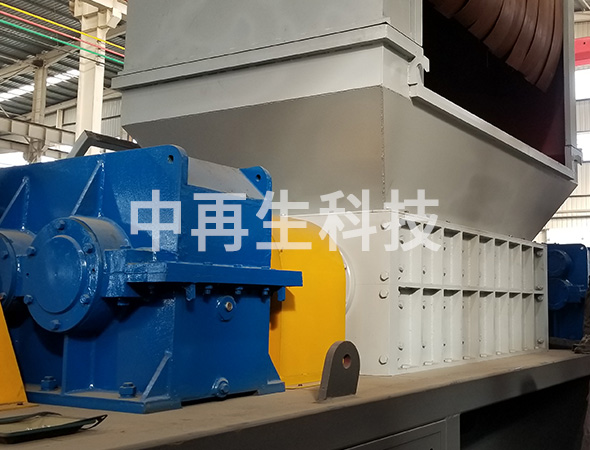

The DS46200 dual axis shredder adopts low-speed rotation and uses a disc cutter to cut, cut, tear, and pull materials. The direct connection worm gear reduction motor is directly installed on the driving shaft of the shredder, and is transmitted to the driven shaft through gear speed change, causing the moving blade of the driving shaft to form relative motion with the stationary cutter head on the housing. The spiral teeth on the drive shaft are arranged in a staggered manner, causing the material to be squeezed, torn, and sheared simultaneously after entering, thereby crushing the material.

With the continuous development of society and the increasing emphasis on resource reuse, the application prospects of dual axis shredders will be even broader. The DS46200 dual axis shredder, as one of the top performers, has a wide range of competitiveness and application prospects in the market due to its powerful processing capacity, efficient crushing effect, and environmentally friendly and energy-saving characteristics.

The integral cutter box is designed and processed as a whole, with high mechanical strength, high stability and reliability; The cutter box is divided into upper and lower parts, which is convenient for overhaul and maintenance and shortens the downtime. The overall annealing treatment eliminates the prestress caused by welding, which is not easy to deform after long-term use, with better comprehensive performance and longer service life.

The tool is made of imported alloy steel, with high wear resistance and moderate toughness. It is processed by high-precision machine tools, with significantly improved mechanical properties and greatly extended service life. The tool can be repaired by surfacing for many times to save the use cost and prolong the service life.

Dual three-phase asynchronous motor + dual planetary reducer drive and hydraulic motor drive are available. The motor + reducer is connected by German standard spline, with stable torque transmission, high precision and good guidance, giving the equipment strong power; Hydraulic drive, stepless speed change, strong material adaptability.

| Model | Power(kW) | Grinding chamber dimension(mm) | Total Weight(t) | Size(mm) |

| DS46100 | 55+55/6 | 1090X1080 | 8 | 5400X2000X2730 |

| DS46120 | 75+75/6 | 1210X1080 | 17.5 | 5520X2000X2730 |

| DS46150 | 90+90/6 | 1570X1080 | 18 | 5880X2000X2730 |

| DS46180 | 90+90/6 | 1810X1080 | 18 | 6120X2000X2730 |

| DS46200 | 90+90/6 | 1810X1080 | 18 | 6120X2000X2730 |

Solution