Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Send e-mailvip@zhongzaisheng.com

The DS61250 Series heavy-duty scrap metal shredder is an advanced industrial machine designed for the efficient shredding and recycling of various types of scrap metal. This equipment is widely used in metal recycling plants, waste processing facilities, and manufacturing industries to process bulky metal waste into smaller, manageable pieces for further recycling or disposal.

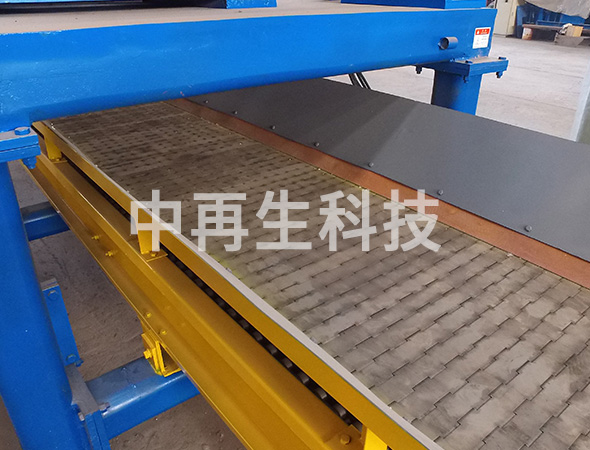

The DS61250 Series heavy duty double shaft shredder is equipped with a powerful set of rotating blades or shafts, which are made of high-strength steel to withstand the intense forces required for metal shredding. These blades rotate at high speeds and apply shear force to cut, crush, and tear the metal into smaller pieces.

Built with robust, durable materials, these shredders can handle large quantities of tough, industrial-grade metal such as scrap steel, aluminum, iron, and copper.

The machine operates with high speed and torque, ensuring that scrap metals are shredded quickly and efficiently, increasing throughput and productivity.

Capable of shredding various types of metals, including car parts, appliances, construction debris, and other scrap materials.

| Model | Power(Kw) | Shredding chamber size(mm) | Main blade quantity(pcs) | Dimension(mm) |

| DS3580 | 22+22 | 840X800 | 28 | 3300X1300X2260 |

| DS40130 | 37+37 | 1350X95 | 32 | 3600X2260X2670 |

| DS46150 | 90+90 | 1570X1080 | 26 | 5880X2000X2730 |

| DS61180 | 55+55 | 1800X1800 | 24 | 5800X3770X4550 |

| DS64250 | 132+132 | 2450X1520 | 32 | 7200X2200X3660 |

Solution