Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Send e-mailvip@zhongzaisheng.com

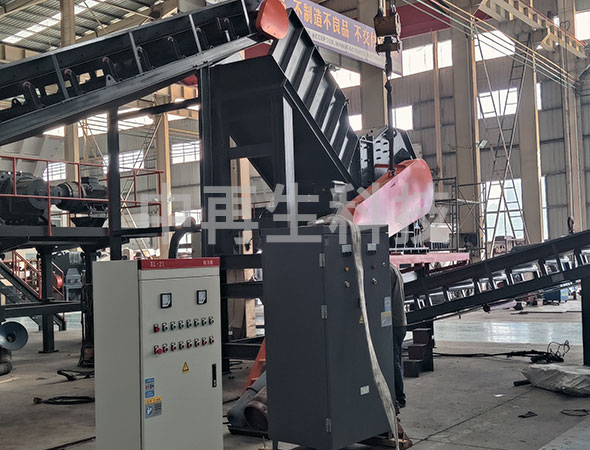

Sc1214 crusher is a kind of mechanical equipment that can crush and reuse the waste aluminum products on the market. The machine base is narrow at the top and wide at the bottom, with good stability. The internal structure of the equipment is a shaft connecting multiple fixed cutter heads. The fixed cutter is S-shaped, which can be overturned and used twice. The fixed cutter plays the functions of forced feeding and forced crushing in the equipment. When encountering flammable and explosive recycled tanks, it can discharge the vent to eliminate the hidden dangers caused by explosion.

The SC1214 scrap steel crusher may be a specially designed impact crusher for processing scrap steel and other scrap metal materials. It uses the impact force between the counterattack plate and the hammer head to break the scrap steel into small pieces or powder for subsequent recycling and reuse. This device may have the characteristics of high efficiency, energy saving, and environmental protection, and is suitable for the crushing and treatment of scrapped cars, scrapped household appliances, and lightweight scrap steel.

The middle of the cutter head is a forging hammer head, which is forged from the steel bar of the train wheel, with good density, economy and durability, and the hammer head is in an arc shape.

In the process of crushing, the waste aluminum materials rotate with the hammer head along with the rapid operation of the hammer head. After a short time of beating and rubbing, the particles form and flow out of the screen at the bottom of the equipment.

The materials that do not meet the specifications are retained in the crushing bin and continue to be crushed until they meet the size of the screen hole, so as to ensure the consistency of the discharge specifications.

| Model | Power(kW) | Feed size(mm) | Average capacity(t/h) |

| SC6050 | 22-37 | 600×800 | 0.3-0.5 |

| SC7080 | 37-55 | 600×760 | 0.8-1 |

| SC8010 | 55-75 | 1000×800 | 0.3-0.5 |

| SC1280 | 75-200 | 1000×1200 | 1.5-2.5 |

| SC1210 | 132-200 | 1200×650 | 3-6 |

| SC1214 | 200-315 | 600×1200 | 0.3-0.5 |

| SC1415 | 55-75 | 1000×800 | 0.3-0.5 |

| SC1680 | 132-200 | 1300×1500 | 3-5 |

| SC1690 | 132-315 | 1000×900 | 5-6 |

| SC1614 | 450-560 | 900×1660 | 750 |

Solution