Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Send e-mailvip@zhongzaisheng.com

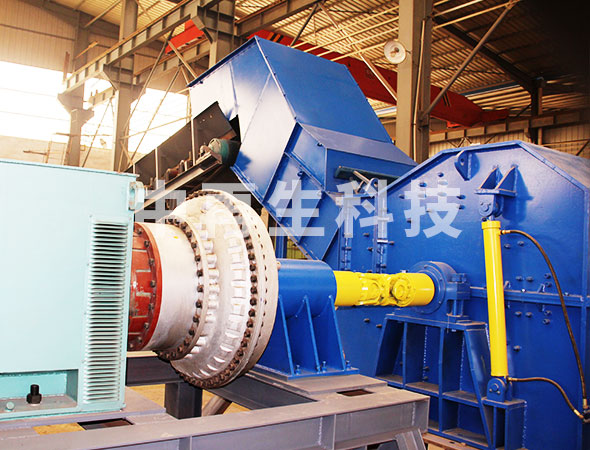

The working principle of SC1415 scrap steel crusher is that under the continuous drive of high-speed and high torque motor, the hammer heads on the crusher rotor alternately strike the scrap steel entering the chamber. Under strong impact, scrap steel is torn and squeezed into a certain specification of crushed steel, which is then processed by sorting equipment to obtain high-quality crushed steel with high purity.

SC1415 scrap steel crusher is widely used in industrial sectors such as metallurgy, mining, cement, chemical industry, as well as in fields such as highways, water conservancy engineering, and construction engineering. At the same time, it can also handle various types of waste car shells, oil drums, and various types of social waste.

The smelting cycle of the scrap crushed by the crusher is relatively short, the crushed steel is uniform, and can be smelted quickly; After processing, the chemical composition of molten steel after smelting is stable and contains low sulfur and phosphorus.

Compared with that before crushing, the recovery rate of crushed steel is greatly improved. Due to the crushing work in the early stage, the smelting process becomes simple, and the power consumption cost per ton of molten steel is greatly reduced.

The crushing process reduces impurities, so as to reduce air pollution and slag; Uniform crushing of steel can effectively increase the lining time in the furnace.

| Model | Power(kW) | Feed size(mm) | Average capacity(t/h) |

| SC6050 | 22-37 | 600×800 | 0.3-0.5 |

| SC7080 | 37-55 | 600×760 | 0.8-1 |

| SC8010 | 55-75 | 1000×800 | 0.3-0.5 |

| SC1280 | 75-200 | 1000×1200 | 1.5-2.5 |

| SC1210 | 132-200 | 1200×650 | 3-6 |

| SC1214 | 200-315 | 600×1200 | 0.3-0.5 |

| SC1415 | 55-75 | 1000×800 | 0.3-0.5 |

| SC1680 | 132-200 | 1300×1500 | 3-5 |

| SC1690 | 132-315 | 1000×900 | 5-6 |

| SC1614 | 450-560 | 900×1660 | 750 |

Solution