Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Send e-mailvip@zhongzaisheng.com

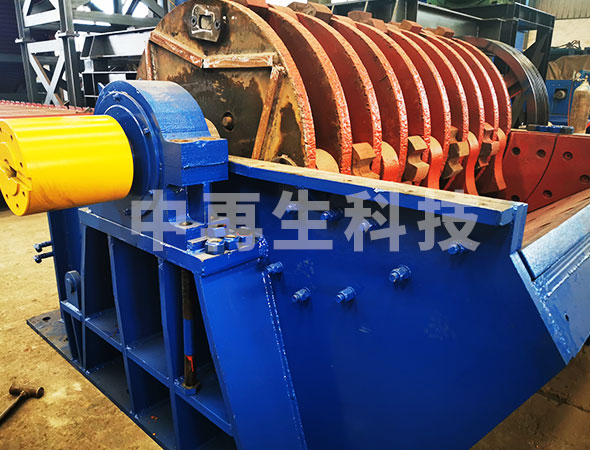

Sc1614 crusher is usually used to process some civil waste copper and iron. Most of these materials are light and thin materials. These materials have uneven quality, complex material composition, easy oxidation and rust, and high sulfur content. Sc1614 crusher can crush, remove impurities, rust and sort these waste metal materials, so as to improve the recovery rate and increase the added value of materials.

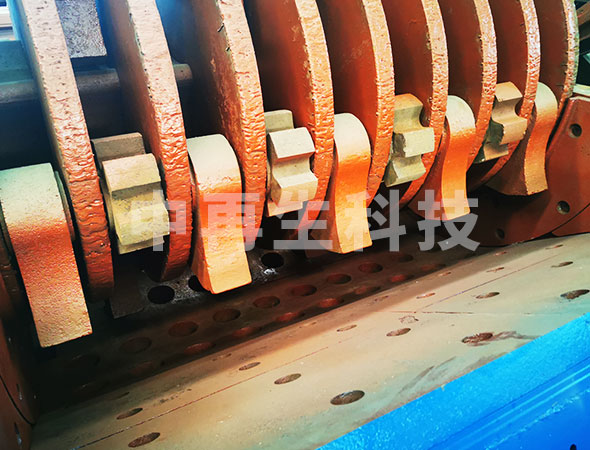

The working principle of a large aluminum scrap crusher is to crush the waste aluminum material through the action of mechanical force. The specific process is as follows: the discarded aluminum material is sent into the crushing chamber of the crusher, and the transmission system controls the operation of the crusher to generate high-speed rotating cutting tools to crush the aluminum material into fragments. When the sieve in the crushing chamber screens the crushed aluminum fragments to meet the required particle size requirements, the screened aluminum fragments are discharged from the discharge port and can enter the next process for further processing.

The equipment body adopts the reinforced structure of extra thick steel plate and diagonal brace to ensure that the equipment can meet the overload operation; The lining plate and hammer head are processed by heat treatment, so the stress is naturally removed, the chemical composition is more stable, and the service time is increased by more than 30%;

The pressing device pre compresses the materials, expands the feeding range and improves the production efficiency. The door shall be set. After the non breakable materials enter the crushing chamber, the user can open the door and discharge them out of the machine body to avoid damaging the crusher.

The hydraulic cover opening device saves time, labor and effort in replacement and maintenance; PLC control system and hydraulic power system, intelligent production saves time and effort, and the equipment operation is clear at a glance.

| Model | Power(kW) | Feed size(mm) | Average capacity(t/h) |

| SC6050 | 22-37 | 600×800 | 0.3-0.5 |

| SC7080 | 37-55 | 600×760 | 0.8-1 |

| SC8010 | 55-75 | 1000×800 | 0.3-0.5 |

| SC1280 | 75-200 | 1000×1200 | 1.5-2.5 |

| SC1210 | 132-200 | 1200×650 | 3-6 |

| SC1214 | 200-315 | 600×1200 | 0.3-0.5 |

| SC1415 | 55-75 | 1000×800 | 0.3-0.5 |

| SC1680 | 132-200 | 1300×1500 | 3-5 |

| SC1690 | 132-315 | 1000×900 | 5-6 |

| SC1614 | 450-560 | 900×1660 | 750 |

Solution