Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Send e-mailvip@zhongzaisheng.com

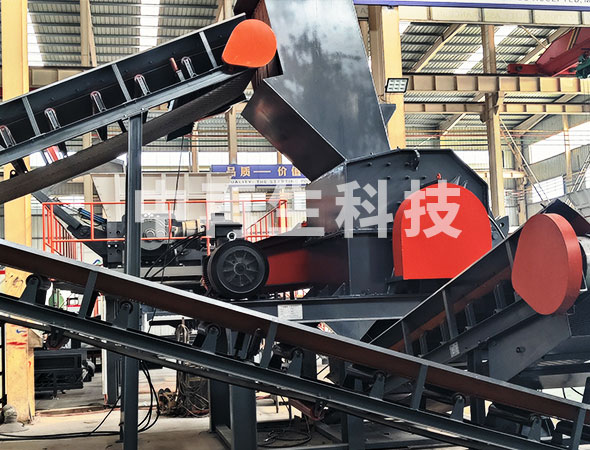

SC1680 Metal Hammer Mill is mainly driven by a motor, which cuts, squeezes, and crushes waste metal materials through the interaction between the blade and the crushing chamber. According to the different types of crushed materials, metal crushers can also be called scrap metal crushers, can crushers, scrap steel crushers, paint bucket crushers, etc. In addition, metal crushers can be divided into dry systems, wet systems, and semi wet systems based on their crushing principles and working methods.

Metal crushers play a key role in the recycling and processing of scrap metals, effectively crushing scrap metals such as scrap steel, scrap iron, scrap aluminum, etc., facilitating further separation and processing.Metal crushers play a key role in the recycling and processing of scrap metals, effectively crushing scrap metals such as scrap steel, scrap iron, scrap aluminum, etc., facilitating further separation and processing. The waste generated during the processing of non-ferrous metals such as aluminum and copper can also be processed through metal crushers for recycling and reuse.

The crushed material particles are uniform, easy to put into the furnace, and the water yield is high during smelting.

The discharge particle size can be adjusted by changing the sieve plates with different pore sizes to meet the diversified needs of customers.

The hammer head and lining plate made of alloy casting are impact resistant and wear-resistant, with low production cost. A cleaning position is reserved for cleaning and maintenance inside the crusher.

| Model | Power(kW) | Feed size(mm) | Average capacity(t/h) |

| SC6050 | 22-37 | 600×800 | 0.3-0.5 |

| SC7080 | 37-55 | 600×760 | 0.8-1 |

| SC8010 | 55-75 | 1000×800 | 0.3-0.5 |

| SC1280 | 75-200 | 1000×1200 | 1.5-2.5 |

| SC1210 | 132-200 | 1200×650 | 3-6 |

| SC1214 | 200-315 | 600×1200 | 0.3-0.5 |

| SC1415 | 55-75 | 1000×800 | 0.3-0.5 |

| SC1680 | 132-200 | 1300×1500 | 3-5 |

| SC1690 | 132-315 | 1000×900 | 5-6 |

| SC1614 | 450-560 | 900×1660 | 750 |

Solution