Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Send e-mailvip@zhongzaisheng.com

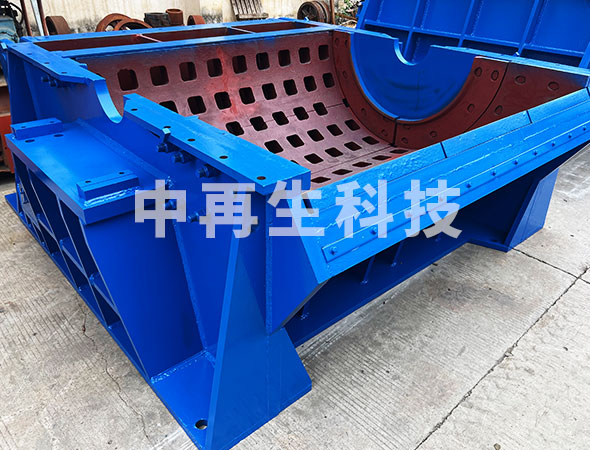

SCL1600 Metal Hammer Mill is mainly used for crushing scrapped cars, scrapped household appliances, and lightweight scrap steel. By crushing scrap steel with a crusher and then using a sorting system to sort the crushed scrap steel, pure and high-quality scrap steel can be obtained.

The working principle of the scrap steel crusher is mainly driven by a high-speed and high torque motor, and the hammer heads on the crusher rotor alternately strike the scrap steel entering the chamber. Under strong impact, scrap steel is torn and squeezed into a certain specification of crushed steel, which is then processed by sorting equipment to obtain high-quality crushed steel with high purity.

The smelting cycle of the scrap crushed by the crusher is relatively short, the crushed steel is uniform, and can be smelted quickly; After processing, the chemical composition of molten steel after smelting is stable and contains low sulfur and phosphorus.

Compared with that before crushing, the recovery rate of crushed steel is greatly improved. Due to the crushing work in the early stage, the smelting process becomes simple, and the power consumption cost per ton of molten steel is greatly reduced.

The crushing process reduces impurities, so as to reduce air pollution and slag; Uniform crushing of steel can effectively increase the lining time in the furnace.

| Model | Inlet width(mm) | Power(kW) | Average capacity(t) |

| SCL600 | 1600 | 475 | 15-20 |

| SCL1000 | 2200 | 750 | 20-25 |

| SCL1200 | 2200 | 900 | 25-30 |

| SCL1600 | 2200 | 1200 | 15-20 |

Solution