Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Send e-mailvip@zhongzaisheng.com

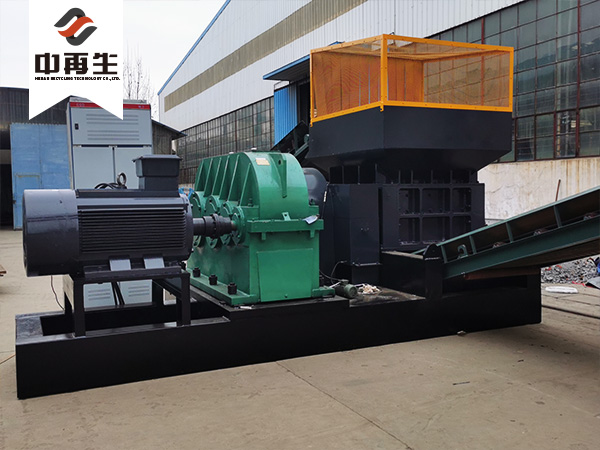

The TG1000 Series Scrap Rebar Double Shaft Shredder is a specialized piece of equipment designed for processing and recycling discarded steel bars, commonly referred to as rebar. These machines are widely used in industries such as construction waste recycling, metal processing, and scrap material management.

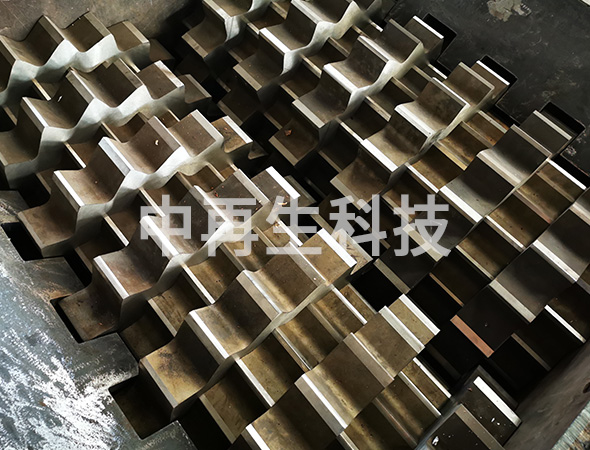

The TG1000 Scrap Rebar Double Shaft Shredder consists of powerful rotating blades or shafts equipped with cutting tools. These blades are designed to exert tremendous force on the steel rebar, breaking it into smaller pieces. The cutting tools are usually made of high-strength alloy steel to withstand the harsh conditions of shredding metal.

Capable of handling large volumes of scrap rebar with high throughput, reducing downtime and maximizing productivity.

Built with robust materials and heavy-duty components to withstand the demands of tough metal recycling environments.

Equipped with powerful motors and sharp blades to efficiently shred steel rebar into smaller pieces.

| Model | Power(Kw) | Shredding chamber size(mm) | Main blade quantity(pcs) | Dimension(mm) |

| DS3580 | 22+22 | 840X800 | 28 | 3300X1300X2260 |

| DS40130 | 37+37 | 1350X95 | 32 | 3600X2260X2670 |

| DS46150 | 90+90 | 1570X1080 | 26 | 5880X2000X2730 |

| DS61180 | 55+55 | 1800X1800 | 24 | 5800X3770X4550 |

| DS64250 | 132+132 | 2450X1520 | 32 | 7200X2200X3660 |

Solution