Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Send e-mailvip@zhongzaisheng.com

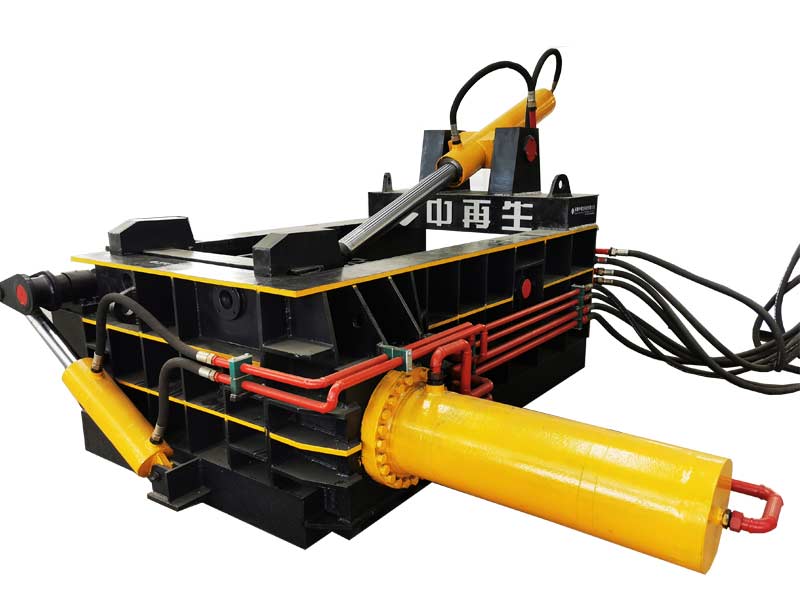

Y81-200 metal baler designed and manufactured by Henan Zhongsheng Technology Co., Ltd. is committed to the recycling and reuse of scrap metal. It is put forward that the waste metal can be packaged by hydraulic pressure to make it into a package with a considerable size, so as to facilitate the recovery, transportation and recycling of the waste metal, so as to put it back into production. In this way, the utilization rate of scrap metal is improved, and the demand for metal resources is alleviated to a certain extent.

The working principle of the metal strapping machine is mainly based on the hydraulic transmission system. By using a high-pressure oil pump to generate strong hydraulic pressure, the piston or plunger is driven to compress metal materials. This process requires the equipment to have sufficient strength and rigidity to withstand enormous pressure, and ensure that the metal material can be uniformly and tightly compacted during the compression process, thereby achieving the goal of reducing volume and increasing density.

The hydraulic packer starts working at the station after feeding, and stops working at the time when the package is pushed out, which is a single working cycle.

There are two forms of bag turning and bag pushing. There are eight extrusion forces ranging from 63 tons to 400 tons, and the efficiency ranges from 0.5 tons / hour to 20 tons / hour.

It adopts a rotary closed cover structure, with a large opening area of the material box, especially suitable for large, empty and thin materials

| Model | Nominal thrust(kn) | Compression chamber size(mm) | Package size(mm) | Equipped with power(kw) |

| Y81-200 | 2000 | 1600*1000*800 | (400-700)*400*400 | 30 |

Solution