Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Feed width:1100x1200mm

Production capacity:15-20t/h

Aluminum can, iron can

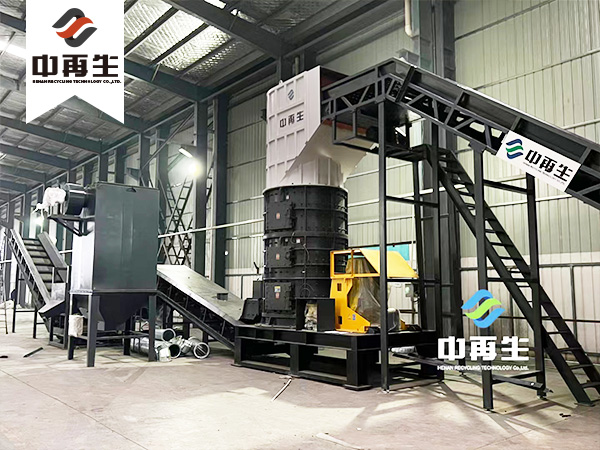

The can recycling, crushing and sorting production line is a specialized equipment system for processing waste cans. It can efficiently crush and sort waste cans, thereby achieving resource recycling and utilization. The production line for recycling, crushing, and sorting cans mainly consists of the following equipment: 1. Metal chain plate conveyor: used to send waste cans into the crusher for crushing treatment. 2. Crusher: Driven by a high-speed, high torque motor, the hammer heads on the rotor take turns striking the cans that enter the chamber, tearing and squeezing them into particles or fragments. 3. Iron remover: used to separate the iron components from the broken cans to improve the purity of aluminum. 4. Dust reduction system: used to collect and process dust generated during the crushing process to protect the environment and the health of workers. 5. Intelligent control system: Implement intelligent monitoring, protection, maintenance, and fault prediction functions for the entire production line to ensure stable operation of the production line.

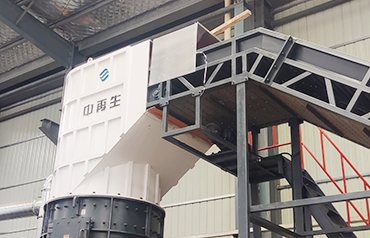

Vsc4 series vertical crushers are equipped with an automatic reverse control system: the electrical part of the vertical crusher is equipped with an overload automatic reverse control system, which can protect the equipment after the equipment is overloaded, reduce the probability of equipment damage due to overload, improve the degree of use, and extend the service life of the equipment to a certain extent.

The aperture of the screen of the vertical crusher can be customized: the aperture size of the screen of the vertical crusher can be customized according to the requirements of users. The equipment adopts special durable rotor disc, unique design, thickened cast steel material, and is heat treated to save power, increase stability, wear resistance, impact resistance and durability.

The vertical crusher has low operation cost and stable performance: the crushed materials from the vertical crusher pass through the vibration conveyor, belt conveyor and magnetic separation system to separate ferrous metal objects, non-ferrous metal objects and non-metallic objects, and are sent out by their respective conveyors for stacking.

Waste cans are transported by a metal chain conveyor to a crusher, which breaks them into particles or fragments. Subsequently, the broken fragments of the soda can were subjected to an iron remover, and the iron components were separated. During the process of crushing and removing iron, the dust reduction system continues to operate, collecting and processing the generated dust. The intelligent control system monitors and controls the entire process in real-time, ensuring the stable operation and efficient recycling of the production line.

| Model | Power(kW) | Grinding chamber dimension(mm) | Cylinder diameter(mm) | Size(mm) |

| VSC4-1200 | 160-250 | 1100X1200 | 1380 | 3300X4300X5100 |

| VSC4-1600 | 250-315 | 1100×1600 | 1700 | 4400X2300X6000 |

Material to be treated: Kitchen scraps

Finished product dimension: 15t/h

Material to be treated: F15 Fighter Aircraft Replaced Wear Parts

Finished product dimension: 2-4t/h

Material to be treated: Trash cans, sofas and other bulky waste

Finished product dimension: 4-8t/h

Solution

Sujet recommandé