Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Feed width:1100x1100mm

Production capacity:15t/h

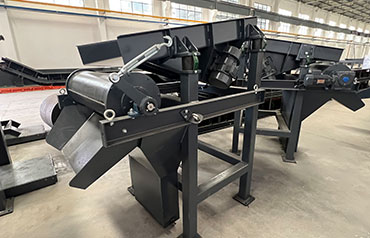

The waste aluminum recycling, crushing, and sorting production line is an efficient waste aluminum processing equipment that can crush and sort various waste aluminum materials to obtain pure and high-quality waste aluminum metal raw materials.The manual sorting part of the waste aluminum recycling, crushing, and sorting production line can perform preliminary sorting on the raw materials to remove impurities and non aluminum metals.The scrap aluminum crushing and fine crushing part is the core part of the production line, usually composed of a scrap aluminum crusher mainframe. Using the basic principle of hammering, the scrap aluminum material is crushed into crushed materials that meet the specifications.

Vsc4 series vertical crushers are equipped with an automatic reverse control system: the electrical part of the vertical crusher is equipped with an overload automatic reverse control system, which can protect the equipment after the equipment is overloaded, reduce the probability of equipment damage due to overload, improve the degree of use, and extend the service life of the equipment to a certain extent.

The aperture of the screen of the vertical crusher can be customized: the aperture size of the screen of the vertical crusher can be customized according to the requirements of users. The equipment adopts special durable rotor disc, unique design, thickened cast steel material, and is heat treated to save power, increase stability, wear resistance, impact resistance and durability.

The vertical crusher has low operation cost and stable performance: the crushed materials from the vertical crusher pass through the vibration conveyor, belt conveyor and magnetic separation system to separate ferrous metal objects, non-ferrous metal objects and non-metallic objects, and are sent out by their respective conveyors for stacking.

The working principle of the waste aluminum recycling, crushing and sorting production line is that first, the raw materials are manually or manually placed on the plate conveyor by a gripper truck and enter the waste aluminum crusher host. Then, driven by a high-speed and high torque motor, the hammer heads on the main rotor take turns striking the object to be crushed that enters the chamber. Through the space formed between the lining plate and the hammer head, the object to be crushed is torn into pieces that meet the specifications. The crushed material leaks out through the sieve holes at the bottom of the crusher and enters the primary magnetic separator through the belt conveyor. Finally, impurities in the metal are separated at the primary magnetic separator. After magnetic adsorption, clean scrap aluminum metal can be obtained on one side for subsequent processing, and non-ferrous metals and impurities absorbed by the magnetic separator on the other side can be separated by secondary magnetic separation or eddy current separation to select iron or other non-ferrous metals mixed inside.

| Model | Power(kW) | Grinding chamber dimension(mm) | Cylinder diameter(mm) | Size(mm) |

| VSC4-1200 | 160-250 | 1100X1200 | 1380 | 3300X4300X5100 |

| VSC4-1600 | 250-315 | 1100×1600 | 1700 | 4400X2300X6000 |

Material to be treated: Kitchen scraps

Finished product dimension: 15t/h

Material to be treated: F15 Fighter Aircraft Replaced Wear Parts

Finished product dimension: 2-4t/h

Material to be treated: Trash cans, sofas and other bulky waste

Finished product dimension: 4-8t/h

Solution

Sujet recommandé