Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|Tel: +86-391-6196111

|E-mail: zhongzaisheng@139.com

|

Feed width:1000x1200mm

Production capacity:15-20t/h

Car wheel hub, motorcycle wheel hub

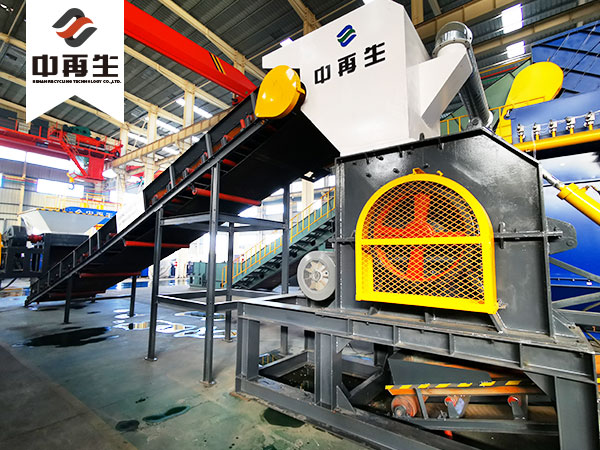

The wheel recycling, crushing, and sorting production line is an automated production line specifically designed for the recycling, crushing, sorting, and reuse of waste wheel hubs. The wheel recycling, crushing, and sorting production line usually consists of the following main parts: 1. Pre treatment system: preliminary cleaning and classification of waste wheels to remove impurities such as soil and oil adhering to the wheels, providing convenience for subsequent processing. 2. Crushing system: Utilizing professional crushing equipment such as shredders or crushers to break down waste wheel hubs into smaller fragments. This step helps with subsequent sorting and melting processes, improving processing efficiency. 3. Screening system: The crushed wheel hub fragments are classified and processed according to different sizes and materials through equipment such as vibrating screens. The screening process helps to separate fragments of different materials, providing convenience for subsequent sorting and reuse. 4. Magnetic Separation System: Use a magnetic separator to separate iron fragments from the mixture. Magnetic separators utilize the differential reactions of different metals to magnetic fields to achieve efficient separation of iron fragments. 5. Other sorting equipment: As needed, the production line may also be equipped with other sorting equipment, such as wind sorting machines, hydraulic sorting machines, etc., to further separate other valuable materials.

The crushed material particles are uniform, easy to put into the furnace, and the water yield is high during smelting.

The discharge particle size can be adjusted by changing the sieve plates with different pore sizes to meet the diversified needs of customers.

The hammer head and lining plate made of alloy casting are impact resistant and wear-resistant, with low production cost. A cleaning position is reserved for cleaning and maintenance inside the crusher.

The working principle of the wheel recycling, crushing and sorting production line is roughly as follows: 1. Waste wheels first enter the pre-treatment system for cleaning and classification. 2. The preprocessed wheel hub is sent to the crushing system for crushing treatment. 3. The crushed wheel hub fragments enter the screening system for grading treatment. 4. The screened fragments enter the magnetic separation system and are separated into iron fragments using a magnetic separator. 5. Other sorting equipment can further separate other valuable materials as needed. 6. The resulting fragments of different materials are processed separately and reused or sold.

| Model | Power(kW) | Feed size(mm) | Average capacity(t/h) |

| SC6050 | 22-37 | 600×800 | 0.3-0.5 |

| SC7080 | 37-55 | 600×760 | 0.8-1 |

| SC8010 | 55-75 | 1000×800 | 0.3-0.5 |

| SC1280 | 75-200 | 1000×1200 | 1.5-2.5 |

| SC1210 | 132-200 | 1200×650 | 3-6 |

| SC1214 | 200-315 | 600×1200 | 0.3-0.5 |

| SC1415 | 55-75 | 1000×800 | 0.3-0.5 |

| SC1680 | 132-200 | 1300×1500 | 3-5 |

| SC1690 | 132-315 | 1000×900 | 5-6 |

| SC1614 | 450-560 | 900×1660 | 750 |

Material to be treated: Kitchen scraps

Finished product dimension: 15t/h

Material to be treated: F15 Fighter Aircraft Replaced Wear Parts

Finished product dimension: 2-4t/h

Material to be treated: Trash cans, sofas and other bulky waste

Finished product dimension: 4-8t/h

Solution

Sujet recommandé